Former Hawker Chief Test Pilot Duncan Simpson talks to Pat Malone about the long life and untimely demise of the Harrier

Published here with the kind permission of AOPA UK.

At a time when we are consigning our Harriers to history it’s worth recalling that in the 1950s, when the Harrier was conceived, Britain had a phenomenally successful fighter aircraft industry, that it sold hundreds of military aircraft to dozens of countries, and that scores of British companies employing tens of thousands of people in high-technology fields prospered on the back of military aircraft exports. In the words of the fabled Four Yorkshiremen, if you told that to t’young folk today they wouldn’t believe you.Prominent among exporters was Hawker which made three of the best jets of the time, the Harrier, the Hawk and the Hunter, all of which were widely exported and bought even by the United States in preference to home-grown aircraft. One man who was intimately involved with the development of all three was Hawker test pilot Duncan Simpson, long retired but keenly aware that working ourselves into a position where we have aircraft carriers with no planes is not a brilliant idea.

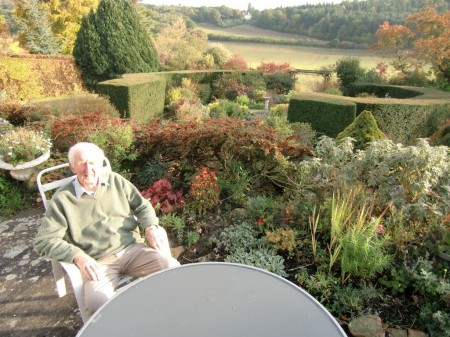

Duncan, latterly Hawker’s Chief Test Pilot, is not one to make political statements in public on defence matters but he clearly shares the bafflement of the Harrier Force at its demise. Tall and distinguished at 82, he speaks in quiet, hoarse tones – the legacy of a post-ejection operation for a broken neck – and he picks his words carefully when discussing defence cuts. “I thought that the Harrier would survive,†he says. “I went up to Wittering for the celebration of the 40th anniversary of the Harrier Force; they’d just come back from Afghanistan and they are intensely proud of the job they’ve done there with the Mk 9, which is a very well-equipped and able aeroplane. I thought they were relatively safe because they are fully developed, at a fraction of the cost of some of the collaborative programs. But the final blow came when I was due to go down to Bristol to celebrate the 50th anniversary of Rolls-Royce Bristol and a first of the Pegasus engine hovers. They were devastated at the news that the Harrier was to be discontinued.â€

Ironically the Harrier was a response to a piece of civil service thinking every bit as questionable as the current one – the infamous 1957 White Paper which foresaw the end of the manned fighter. Duncan recalls: “Sir Sydney Camm (Hawker’s Chief Designer, responsible for aircraft as diverse as the Hart, the Hurricane and the Harrier), sat back in his chair and said, ‘Look, this White Paper is doom to the industry if we’re not careful, and for the Royal Air Force and the Royal Navy too because it doesn’t see a future for manned aircraft… we at Hawkers have got to do something fairly drastic.’ So he wrote Sir Stanley Hooker (Bristol Aero Engines Chief Engineer) a letter of which I still have a copy. Sydney didn’t write letters very often. It started off in the usual way:

“Dear Hooker. I hear you are looking at VSTOL. What are you doing? Come and see me. I don’t want another flying test bed. I’m not having it. I don’t like the Rolls-Royce Derby solution. Signed, S Camm.”

(Rolls-Royce was working on a fighter with eight lifting engines.)

So Stanley Hooker went up to see him, and they got on well. Stanley was a great personality, and so was Sydney. Ralph Hooper of Hawkers was brought in and instructed to wrap an airframe around a vectored thrust engine and the aircraft was built and flown within 18 months – the P1127.

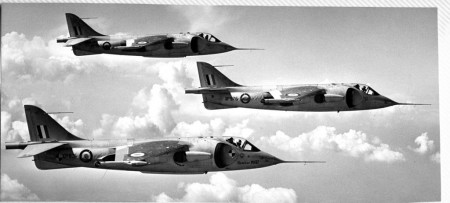

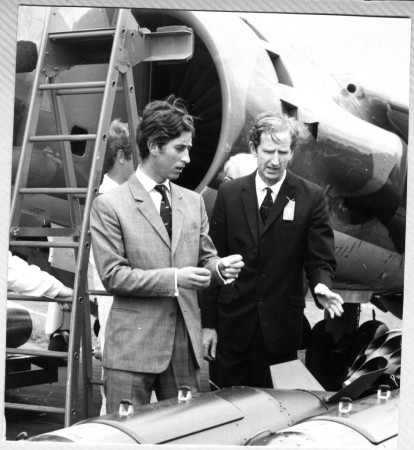

The story of the development of the P1127 into the Kestrel and the Harrier has been well and often told, but while the civil servants never accepted that they were wrong about the manned fighter, the Ministry of Aviation soon took an interest in what Hawkers and Bristol were up to, eventually ordering two P1127s for research and four more for development. Significant support came from the Americans through the Mutual Weapons Development Program. Five more prototypes were built between 1961 and 1964 and finally three nations, the USA, Britain and Germany, jointly ordered nine aircraft – by then named the Kestrel – for evaluation by a Tripartite Squadron, and Duncan Simpson was given the job of training the pilots. “The Kestrel was a super platform because it was a fairly straight forward development of the P1127 prototypes – in fact the sixth prototype was virtually the same as the Kestrel in planform,†he says. “The evaluation programme started on time and it finished on time, and the Americans thought so much of it that they took six aeroplanes back to the United States. The next milestone what was the purchase by the US Marine Corps, who came across to fly it in 1968 after the Farnborough show. At the same time the RAF was selecting pilots to form the Harrier conversion team. They flew five hours each on the aeroplane, covering everything the Harrier could do, then we flew the aircraft up to Wittering and that was the start of the Royal Air Force Operational Conversion Unit. And it all came out of Sydney Camm’s determination that something drastic had to be done to save the manned fixed-wing fighter for the services. He had to cancel two Mach 2 projects, the P1121 prototype and the P1129, because he realised they wouldn’t survive; TSR2, from the opposite camp, wasn’t going to survive, and Sydney was wise enough to realise this.â€

Duncan Simpson’s family were medical men for four generations, tramping the Scottish highland tracks with their toolbags and performing rudimentary surgery in remote crofts. His father Bertie Soutar Simpson was the first general surgeon to be appointed in Sutherland; today an air ambulance can deliver any sufferer in his vast beat to hospital in minutes. But there was a black sheep; Duncan’s maternal uncle Duncan Menzies had joined the Royal Air Force in the 1920s and later joined Faireys as chief test pilot at Ringway. He did the first flight of the Fulmar and saw it into service. To his young nephew’s mind this was better than cutting up crofters; in fact Duncan had thought of little else but aviation since his grandmother had taken him to see Alan Cobham’s Flying Circus at Tain near Inverness in 1934. But when his time came it was 1945 and the RAF had a surfeit of pilots, so young Duncan won a place at the de Havilland Aeronautical Technical School at Hatfield. What he learned there formed the cornerstone of his career as a test pilot. At de Havilland, you started at the beginning – Duncan’s first job was to build his own toolbox. He spent a year in the school workshops, some of it working on the Wright Flyer replica project for the Science Museum, for which he constructed wing ribs. “Three years later I was present when the finished product was handed over to the Museum,†he says. “It was the only occasion on which I met Sir Geoffrey.â€

It was an extraordinary time to be at de Havilland; the company was producing and designing a vast range of aircraft, military and civil, piston and jet, with the world’s first jet-powered airliner, the DH106 Comet, coming to the prototype stage. Duncan moved from the workshops into the Experimental Department, working on the tailless DH108, the Ghost Vampire and late developments of the Mosquito and the Hornet. He completed the four-year Aircraft Design Course, which led to an Associate Fellowship of the Royal Aeronautical Society, and won the prize for the best final year apprentice.

As a de Havilland student he could have learned to fly at the subsidised rate of 30/- an hour (£1.50). “I was not going to waste my time doing that,†he says. “I wanted to be taught to fly by the RAF, which is the best way of doing it, really.†At the end of his apprenticeship the RAF duly sent him to No 6 Flying Training School at Tern Hill, and Duncan took to flying like a swallow. He learned the basics on the Percival Prentice then flew 100 hours on the Harvard before being selected for training as a fighter pilot. At Middleton St George he learned to fly the Meteor, then went to Stradishall to be taught how to fight in it. He was sent to 222 (Natal) Squadron flying the Meteor 8 at Leuchars. “It was a marvellous tour. We flew over the North Sea on patrols, high-altitude interceptions, low level through the Scottish mountains. I flew seven days a week – I used to fly targets for the Auxiliaries, fly the ATC cadets in Tiger Moths, anything to get flying. I flew 1,000 hours on that tour, most of them on Meteors.â€

He suffered a bird strike which shattered the aircraft’s canopy and drove the bullet-proof windscreen back into the cockpit; he managed to land back at Leuchars, freezing cold and covered in fragments of herring gull but otherwise unharmed. Duncan was never sold on some of the RAF’s training requirements for the Meteor. “A lot of aircraft and pilots were being lost to accidents through questionable training procedures,†he says, “in particular during asymmetric training. To train people for emergencies at slow speeds on one engine in the Meteor was quite a demanding process. A lot of people came unstuck, but in fact they were very reliable engines and things rarely went wrong with them in the real world.

“Another thing was the absence of navigation aids. You had people in Scotland running into mountains because they didn’t know where they were. Here they were flying a high performance aeroplane, and our let-down if we lost our radio was to fly out over the North Sea, turn inbound and hope you turned the right way when you got to the coast. I tried very hard to improve things when I got to Hawkers. I got TACAN installed in the Harrier to update the first-generation inertial navigation system, but I had to battle the Air Ministry to do it.â€

Duncan’s aim was to get onto the Air Fighting Development Squadron at RAF West Raynham, where new fighters were evaluated. After two years with 222 Squadron he saw his chance. “I told my Wing Commander at Leuchars that that was the squadron I wanted to go to. He was an ex-Battle of Britain friend of the CO, Wing Commander Bird-Wilson. When he rang him up I was in the outer office, and I thought my future was doomed because he said, ‘I have a young lunatic here who flies seven days a week, who likes to do aerobatics at low-level, who is a great enthusiast and who was an aircraft engineer by training, and he’s dead set on joining you’. Bird-Wilson sent for me and I got down to West Raynham in a snowstorm and saw this little man covered in medals sitting behind his desk. He told me that it was most irregular, and I’d have to go back to my squadron and see what happened. I was posted there within three weeks, and Bird-Wilson became a long-time friend, until he died.

“There were just eight pilots in the Air Fighting Development Squadron, and the attraction was flying new aeroplanes – the Hunter, the Swift, the F86E Sabre; it was the time of the introduction of the transonic fighter. We had the Swift Mk 1, the Hunter Mk 1 with the Avon and the Hunter Mk 2 with the Sapphire. We got the Venom, which I had worked on in the Aerodynamics Department at Hatfield, which was known as the ‘thin wing Vampire’ to try to get it flying at higher Mach numbers.

“When I was asked which aircraft I want to specialise in I had no hesitation in choosing the Hunter. It just looked right. I’d seen Neville Duke flying the 1067 prototype at Farnborough and I said to myself, that’s the aircraft which is going to succeed. The Hunter 9 and 10 probably became the best engine and airframe fighters of the late 50s and early 60s, and they could hold their own with anything in the world. We were like a squadron with six different types of aircraft. It was a plum job, there’s no doubt about it.â€

And then he left the RAF. “I was four years behind everyone else,†he says. “At the time the RAF only recognised university degrees. The refusal to recognise my background meant I would be 29 before I made Squadron Leader, and until that was put right I was reluctant to accept a permanent commission. As it happened, it worked to my advantage. Neville Duke rang up one day in 1954 and said he urgently needed a test pilot at Hawkers, and the RAF didn’t want to release anyone who was on a permanent commission. So I took the job.â€

Hawkers were busy. Duncan began production test flying on the Hunter, but gradually he became involved in development work. Two years into the job Duncan married his wife Pat and settled down to raise a family; later they moved into a rambling mansion near Guildford in which they still live.

In 1954 his world was populated by men whose names are near-mythical today; Neville Duke, Bill Bedford, Hugh Merewether, and of course, Sir Sydney Camm. Sir Sydney, the self-taught son of a carpenter, had to deal with government, and it didn’t sit well with him. “He used to call it ‘the Misery of Defence’,†says Duncan. “He used to come down to sit with us in the pilots’ office at Dunsfold. He was always interested to know what our views were, and of course we used to go up and see him at Kingston.â€

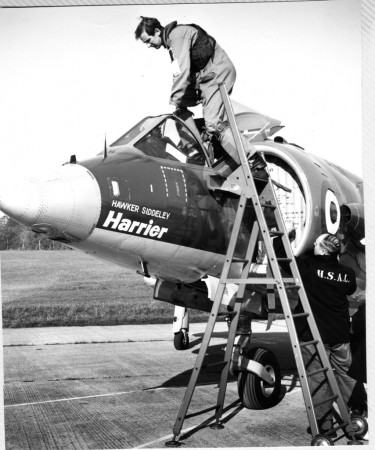

Initial test flying on the P1127 was done by Bill Bedford and Hugh Merewether, and Duncan was the third pilot to fly it. “I had listened a lot, and I’m a good watcher, and I transitioned onto the aircraft largely by listening to Hugh,†he says. “Out of my own experience I did the training for the Tripartite Squadron and I wrote the training syllabus for the RAF pilots on the Harrier in the days before there was a two-seater.â€

The two-seat Harrier almost ended his career on his first flight in it. “Hugh was going to the 1969 Paris Air Show with the single-seater, and he asked me to come down from Wittering to continue the prototype testing. Eight minutes after takeoff I had just started a 450 kt flutter clearance run and I had a complete engine failure at 3,000 feet. I was 12 miles from Boscombe and turned towards it, raising the nose to reduce speed to 260 kt, which was the engine relight speed. I was halfway through my second attempted relight when I realised I wouldn’t make it to Boscombe, so I tried to put it on Larkhill Range. I left the aircraft at 100 feet, according to the instrumentation, on James Martin’s new Mark 9 seat with the big rocket – otherwise I might not have got away with it, I think; it was the first live ejection of the Mk 9. I shot up to 300 feet and felt the drogue deploy as I saw the sky between my feet. The aircraft landed with wheels and flaps down, but I wasn’t in it. And of course it was full of fuel and caught fire. I was sitting in the ejector seat just above the fireball and was blown away from it by the wind. I landed 100 yards away in a certain amount of pain because I’d broken my neck on the canopy on the way out, but Boscombe had a helicopter and a doctor on scene within 20 minutes.â€

A month later surgeons performed a bone graft on Duncan’s neck, requiring entry from the front. The affected his voice, which remains hoarse to this day. Two months after the incident he was out of hospital and five months later he’d regained his medical and was once again flying the Hunter. Within eight months he was back in the Harrier. The instrumentation and the photographic evidence from the crashed aircraft showed that Duncan had been faced with a complete fuel system failure. The knives on the ejector seat had failed to shatter the T2’s canopy, so Miniature Detonation Cord was quickly introduced to Harrier and other canopies. Duncan was told by the surgeons that the anterior bone graft had actually strengthened his neck so he didn’t really fear the possibility of another ejection – although fortunately he didn’t have to make one.

“There were one or two Hunter incidents which we were lucky to get away with,†he says, “but by and large it was a trouble-free flying career. I had one incident in 1962 when I was flying the last production Sea Fury. At 2,000 feet I pulled up into a loop, held the aircraft inverted at 5,000 feet and started a slow roll. To my horror the ailerons jammed and the slow rolls continued while going downhill. By 4,000 feet I was beginning to run out of ideas, but I remembered some stick jams with the Hunter’s Fairey hydro-boosted controls. We would apply more stick to increase the roll rate, upon which a pawl dropped into a slot and cleared the jam. Though it was hardly relevant in this case it was the only option left to me, and as I did this the jam cleared. I missed the South Downs by 500 feet. After I’d landed we found a loose 3/8th inch bolt lying in the bottom wing skin.â€

Like the Harrier, the Hawk was begun with company enterprise, rather than chasing a government specification. “We knew that the Gnat would not last more than about 10 years because it wasn’t really good at training people to handle the bigger fighters,†Duncan says. “We thought about redesigning the Hunter with a side-by-side advanced training cockpit, but in the end we ended up building a whole new aeroplane, which was the P1182. Following Sir Sydney’s doctrine of not sitting back and waiting for the ‘Misery of Defence’, we started on it. We had all the people who developed the Hunter and the Harrier, and the ex-Folland people and we did it in record time. The Hawk was delivered to Boscombe Down two years after first flight, which was remarkable really. It went to the Air Force up at Valley two months later. Here we are 36 years on and there’s 24 of them on the line at Valley, training pilots, and the new Hawk going into service next year with the advanced weapons systems.

“With project pilots Andy Jones and Jim Hawkins I saw the Hawk off the drawing board right the way through the design, down to Dunsfold, manufacture, then the first flight. We had 10 days to go before the Farnborough show and I took it there on its tenth flight. It was a good design from the start, although we had to do some refinement work on the wing to improve the stalling characteristics, with vortex generators and fences, and leading edge splitters to provide buffet warning. We built four aeroplanes and we asked Boscombe to come and fly them with us, to shorten the time for clearance, and that was successful.

“The Hawk was classified as a subsonic advanced trainer, but we soon realised that it was going to go faster than was specified. We got to a 25° dive and it was up over Mach .9. I was talking to the Chief Designer and said, by the way, next flight we could be going transonic. There was a loud silence on the other end of the telephone. Then he said, ‘But we have no clearance’. To which I replied, ‘Well, get it, and quickly.’ In the end it went supersonic rather easily and we got Mach 1.18 out of it. It’s become a student exercise to go supersonic now, although it’s academic. Same with the Hunter – transonic, but very seldom used.â€

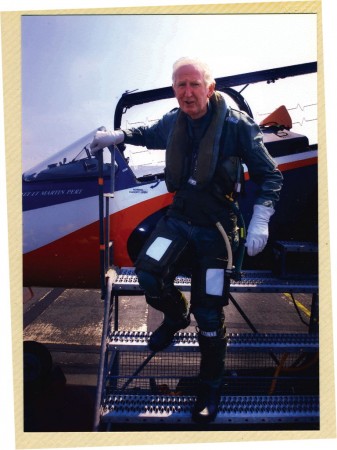

The Harrier Team 30 years on 1999: Richie Profit, Pete Dodworth, Duncan Simpson, Dick Lebrocq, Bruce Latton

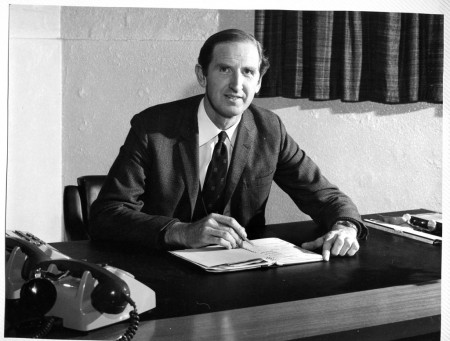

Duncan became Hawkers’ Chief Test Pilot in 1970 and joined the local Board. He says: “At Hawkers it was very important that the Chief Test Pilot – and this goes back to Neville Duke, and George Bullman, who was a director of a company during the war years – always had direct access to the Chairman, the Managing Director, and the General Manager.â€

Duncan retired from test flying at 50 and was made responsible at Hawkers for looking after the Hawk and the Harrier in service. Then he was offered the job of Deputy Director of the Society of British Aerospace Companies, which he did for 15 years while continuing to fly aircraft like the Lysander and the Hurricane for the Strathallan Collection. Honours have come his way; the Queens Commendation for Valuable Service in the Air, awarded following the Harrier T2 ejection, the OBE in 1973, GAPAN’s Derry Richards Medal, the Royal Aeronautical Society’s Alston medal, he is a Fellow of the RAeS, of the Society of Experimental Test Pilots and of the Institute of Mechanical Engineers, Chairman of the Historic Aircraft Association, President of the de Havilland Technical School Association, and he was Master of the Guild in 2002.

Does the Harrier story offer any clues as to how we might handle the current predicament? We live in a very different world, one in which no corporation could embark on a costly and risky private venture in the defence field. We have no Camm, and we have no Hooker. Hawker’s Kingston factory is now a housing estate (with names like Kestrel Close, Camel Grove and Wittering Close), Weybridge is a housing estate, Hatfield is a housing estate; Dunsfold is where they film Top Gear. Says Duncan: “It’s beyond me to comment on how we’ve managed to arrive where we are, but having grown up in the industry I feel very strongly about it. The Hawk was the last project we did at Kingston, and it was delivered on cost and on time. I’m sure that could not have been achieved as a collaborative programme. There are certain hard-core bits of British industry which continue to go right, and the fact that the Hawk and the Harrier are still in service after 40 years is testimony to that.â€

Recent Comments